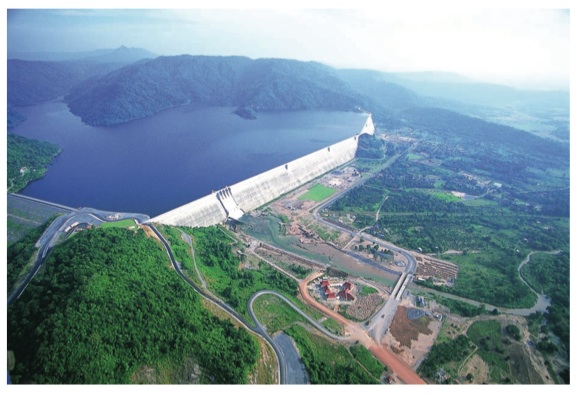

Project Name: Khun Dan Prakarnchon Dam

Firm Name: TEAM Consulting Engineering and Management Co., Ltd.

Associated Firm: ASDECON Corporation Co., Ltd./ COYNE ET BELLIER

Location : Nakhon Nayok Province, Thailand

Project Owner: Royal Irrigation Department

Type of Project: Water resources development

Value of Project: 6,450 MB

Period: July 1999 – January 2005

Project Features: Located in Ban Tha Dan, Hin Tang Sub-district, Muang District, Nakhon Nayok Province, Khun Dan Prakarnchon Dam comprises a roller-compacted concrete dam, a saddle dam, and a reservoir with the retention capacity of 224 million cubic metres of water. Its crest is 2,594 metres long and 93 metres high. At the dam site, there are other appurtenant structures including diversion structures (during the construction), spillway, bottom outlet, river outlet, and irrigation outlet.

This dam is the world’s largest roller-compacted concrete dam (recorded in 2006). Made of 4.84 million cubic metres of roller-compacted concrete, the dam contains the highest amount of this material, construction-wise, in the world.

The main construction works of the project are:

- Excavation and blasting of 1,550,000 cubic metres of rock for the dam foundation.

- Blasting and crushing of 5,000,000 cubic metres of rock from the quarry in order to produce aggregates for the RCC and CVC (Conventional Vibrated Concrete).

- Drilling and grouting of drainage and grout curtains (total length of drill hole is 397,000 metres)

- Placing of 5,470,000 cubic metres of RCC and 558,000 cubic metres of conventional concrete.

Construction of the dam commenced with the rock excavation from approximately 29 m MSL down to about 19 m MSL. Rock excavation included underground drainage and grouting galleries of 3 metres diameter over a total length of 2 kilometers.

With the pouring of the leveling concrete on the base rock foundation, work on consolidation grouting commenced. Consolidation grouting aims to fill voids, fracture zones and cracks below the surface of the excavation; to strengthen and watertight the superficial rock which has been subject to decompression and fracturing during the excavation work; and to fill shrinkage fissures at the rock/concrete interface.

Engineering Highlights

The RCC technique was selected for the dam owing to its solidity, reduced construction time frame and relatively low cost. Common factors in the RCC approach are a high-speed construction and a no-slump consistency that allows the mixture to be compacted by large vibratory rollers.

For this project, lignite fly ash has been introduced as a cement replacement in order to reduce the amount of cement used, to save the material costs, to reduce the heat of hydration and to increase the workability of the mix, and the long -term strength development of the dam. The benefit of this method is the usage of the byproduct of lignite combustion from the Mah Moh Power Plant in Lampang. The mix proportion used at the Dan consists of 1,400 kilograms of course aggregate, 700 kilograms of fine aggregate, 60-80 kilograms of fly ash, and 80-90 kilograms of cement.

Benefits of the Dam

Khun Dan Prakarnchon Dam ensures water supply and an efficient irrigation system for 185,000 rai of farmland of more than 9,000 families. Due to its huge retention capacity, water supply is now stable, thus lessen the problem of flood and drought. Finally, the acid soil problem would be solved as well. The reservoir also serves as a fish breeding area and domain for aquaculture.

Apart from irrigation benefits, Khun Dan Prakarnchon Dam is major tourist attraction of Nakhon Nayok. Tourists can admire its grand structure and enjoy various leisure activities around the dam site. This is a haven for ecotourism where visitors can trek, windsurf, kayak, or go rafting in Khao Yai National Park A museum and recreational centres are also available to cater to the various needs of tourists.